FIBERS FOR FIBER LASERS: PC fibers make capable femtosecond-pulse amplifiers

One big advantage that fiber lasers have over bulk solid-state lasers is the inherent waveguide nature of the fiber gain medium, which results in increased spatial-mode stability under changeable operating conditions. These changes can include operator adjustments to the laser’s optical power, as well as fiber movements such as vibration or repositioning of system components.

Because femtosecond-laser systems in particular tend to be intricate and finicky to begin with, designers of femtosecond lasers and amplifiers are increasingly turning to the use of fibers when they can. In femtosecond systems, photonic-crystal (PC) fibers have an additional advantage—the ability to be tailored. Changes in PC array spacing and type, hole diameters, filling material, and so on allow properties such as optical dispersion to be customized to fit very specific needs.

Here, the use of PC fiber in two very different femtosecond fiber systems—a highly stable master oscillator/power amplifier and a high-peak-power amplifier—illustrates the versatility of PC fibers for creating and shaping ultrafast light pulses.

Monolithic ytterbium-doped fiber laser

For many uses of high-repetition-rate femtosecond lasers in research, biomedical systems, or micromachining, a stable average power is desired. However, laboratory tabletop modelocked femtosecond lasers are sensitive to temperature and other changes, and are often hugely complex. An all-fiber master oscillator/power amplifier developed by a group at DTU Photonik, Technical University of Denmark (Lyngby, Denmark) is intrinsically stable, operating with a maximum fluctuation in power of no more than 7.85 × 10-4 over a six-hour period.1, 2

The system is based on standard ytterbium (Yb)-doped polarization-maintaining (PM) singlemode fiber for gain, a section of PM PC fiber within the cavity for dispersion management and laser stabilization, and a second type of PC fiber outside the cavity for pulse compression; it delivers 210 mW of average power, with a pulse duration of 297 fs in the main peak, a repetition rate of 28.77 MHz, and a total energy per pulse of 7.2 nJ (with 56% of that in the main peak).

The Yb-doped fiber is pumped with a 974 nm laser diode. The 1.21 m section of intracavity PM PC fiber has anomalous dispersion and an all-solid structure. The silicon dioxide (SiO2) matrix holds a hexagonal array of germanium-doped (Ge:SiO2) rods and two boron-doped (B:SiO2) stress rods surrounding the SiO2 core. Light is guided via total internal reflection in one plane and by the fiber’s photonic bandgap in the orthogonal plane. The intracavity PC fiber passively stabilizes the laser via a nonlinear optical limiting mechanism: the stronger pulses undergo stronger self-phase modulation, broadening their spectral bandwidth, a portion of which is partially attenuated by the wavelength-dependent loss of the cavity.

The laser-cavity output then enters a 35 m long section of PM singlemode fiber, which broadens the pulse output to 12 ps, reducing the peak pulse intensity so that it won’t damage the amplifier. Two chained singlemode amplifiers boost the power, producing 17.3 ps pulses. Finally, a 21 m section of hollow-core PC fiber with an attenuation coefficient of 0.076 dB/m serves as the pulse compressor.

The laser is self-starting and at higher powers enters a Q-switched modelocking phase, followed by a stable harmonic modelocking phase. The pulse exiting the cavity has a near-perfect Gaussian temporal shape, but the final pulse is accompanied by small side pulses. However, the researchers say that the pulse shape can be improved in the future by creating parabolic pulses, which can be compressed with high quality.

The modelocking stability of the system was monitored over a four-day period of continuous operation, showing no undesirable Q-switched modelocking events. Moving the fibers and even kicking the tray in which the system sits does not disrupt the laser. Bending a fiber to a 1 cm bending diameter, however, does disrupt lasing—but only until the fiber is released.

The system was put in a temperature chamber that was varied between 10°C to 40°C; stable modelocking was maintained over this range, with a decrease in average power of 9.8% at 40°C. Cooling to 10°C returned the laser to its original output.

The stability of such a laser system would be valuable in situations where high-repetition-rate femtosecond pulses are used to excite a nonlinear medium—for example, to create supercontinuum light or to initiate multiphoton processes for biomedical research. Dmitry Turchinovich, one of the researchers, says that his group will be exploring use of the laser as a source for all-fiber nonlinear frequency conversion, with primary applications in biophotonic imaging and spectroscopy.

Large-pitch PC-fiber amplifier

Very high peak-power femtosecond-laser output (in the gigawatt region at kilohertz pulse-repetition rates) is of interest to those who are pursuing applications in machining, high-harmonic generation, or other uses that demand the ultra-intense electromagnetic fields that such lasers can generate. While optical fibers, with their small cross-sections and resulting damaging high peak intensities, would not seem to be the first choice as components in high-peak-power femtosecond lasers, in reality this is not always so. Fibers enable high single-pass gain, resulting in simple, rugged setups, and produce excellent beam quality as well.

One way around potential fiber damage is to use very large mode-area fibers that have core diameters above 50 µm. For such applications, PC fibers with solid cores and claddings that contain arrays of air holes fill the bill.

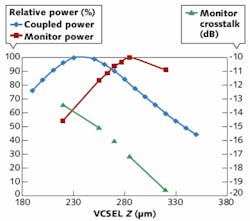

Researchers at the Freidrich-Schiller-University Jena and the Fraunhofer Institute for Applied Optics and Precision Engineering (both in Jena, Germany) have experimentally demonstrated a PC-fiber-based chirped-pulse-amplification system that produces pulses with 3.8 GW peak power, 2.2 mJ energy, and 480 fs duration—resulting in an 11 W average power (see figure).3 The PC fiber used for the amplifier is Yb doped and has a mode-field diameter of 105 μm. Because the array pitch is large (missing only one central hole to define the core), higher-order modes sustain higher losses at the core/cladding border, and thus lower-order modes are preferentially transmitted.

A titanium:sapphire laser generates seed pulses at 1028 nm that travel through a pulse stretcher consisting of 100 m of PM singlemode fiber with a 6 μm core diameter. The stretched pulses are then amplified to a 250 mW average power in a Yb-doped fiber-amplifier stage, which also has a 6 μm core; next they are stretched to about 3 ns by a reflection-grating stretcher. A commercial phase-shaping device and a spatial light modulator use an iterative algorithm to compensate for effects that degrade the pulse quality. Acousto-optical pulse picker reduce the pulse rate, sending 40 μJ pulses into the main amplifier.

The 1.3 m Yb-doped PC main-amplifier fiber has a doped core index carefully matched to the cladding index to eliminate either step-index guidance or a depressed center index that could degrade beam quality. To operate properly, the fiber must be kept as straight as a rod. The output beam quality (M2) is 1.2 and 1.3 in orthogonal directions at a low 0.5 mJ pulse energy and degrades to 1.5 and 1.8 at maximum pulse energy. This degradation can be avoided in the future by changes in the cladding design, say the researchers. In the last stage, the pulses are recompressed by a dielectric compression grating.

The 3.8 GW peak power is the highest ever directly produced by a fiber amplifier. In addition to changes in fiber design, the researchers believe that even higher peak powers can be reached by broadening the spectral bandwidth of the pulses. As a result, scientists may be able to exploit peak powers that have previously been produced only by more complex bulk solid-state laser systems.

REFERENCES

1. X. Liu et al., Opt. Exp., 18, 15, 15475 (July 19, 2010).

2. X. Liu et al., Opt. Lett., 35, 913 (2010).

3. T. Eidam et al., Opt. Exp., 19, 1, 225 (Jan. 3, 2011).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.