A new ChemCam, SuperCam, will be headed to Mars

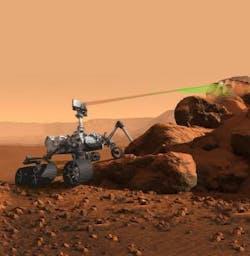

A new incarnation of the ChemCam spectroscopy system that has been exploring Martian rocks aboard the Curiosity Rover will be headed to the Red Planet as part of NASA's Mars 2020 mission. SuperCam builds upon the capabilities demonstrated aboard the Curiosity and will allow researchers to sample rocks and other targets from a distance using ChemCam's Laser-Induced Breakdown Spectroscopy (LIBS) technology.

SuperCam adds another spectrum to its laser for Raman and time-resolved fluorescence spectroscopy. It also will add color to its high-resolution visible imaging capability as well as visible and infrared spectroscopy. The updates enable SuperCam to provide fine-scale mineralogy, chemistry, organic detection, and color images, with the added bonus of being able to dust off a surface via laser blasts.

“We are extremely excited to be going to Mars again,” said Los Alamos National Laboratory (LANL) planetary scientist Roger Wiens, Principal Investigator of the newly selected SuperCam team and current principal investigator of the Curiosity Rover’s ChemCam Team. “More importantly for the mission, I know SuperCam is the very best remote sensor that NASA can have aboard.”

In addition, LANL will build the detector electronics for the Scanning Habitable Environments with Raman & Luminescence for Organics and Chemicals (SHERLOC) instrument. SHERLOC is a spectrometer that will provide fine-scale imaging and use an ultraviolet laser to determine fine-scale mineralogy and detect organic compounds. It will be the first ultraviolet Raman spectrometer to fly to the surface of Mars and will provide complementary measurements with other instruments in the payload.

SuperCam is a continuing effort between LANL and the IRAP research institution in Toulouse, France, and the French Space Agency (CNES), with additional collaboration from the University of Hawaii and the University of Valladolid (UVA) in Spain. According to NASA, agency managers made the instrument selections for the upcoming mission out of 58 proposals received in January from researchers and engineers worldwide.

The Mars 2020 mission is intended to advance knowledge of how future human explorers could use natural resources available on the surface of the planet. Designers of future human expeditions can use this mission to understand the hazards posed by Martian dust and demonstrate technology to process carbon dioxide from the atmosphere to produce oxygen.

Conard Holton

Conard Holton has 25 years of science and technology editing and writing experience. He was formerly a staff member and consultant for government agencies such as the New York State Energy Research and Development Authority and the International Atomic Energy Agency, and engineering companies such as Bechtel. He joined Laser Focus World in 1997 as senior editor, becoming editor in chief of WDM Solutions, which he founded in 1999. In 2003 he joined Vision Systems Design as editor in chief, while continuing as contributing editor at Laser Focus World. Conard became editor in chief of Laser Focus World in August 2011, a role in which he served through August 2018. He then served as Editor at Large for Laser Focus World and Co-Chair of the Lasers & Photonics Marketplace Seminar from August 2018 through January 2022. He received his B.A. from the University of Pennsylvania, with additional studies at the Colorado School of Mines and Medill School of Journalism at Northwestern University.